NEGOI project featured in National Lithuanian television, TV SHOW Curiosity Gene.

To see the video footage click the link bellow (from 13:24 to 25:49) :

Translated interview text:

Rolandas Maskoliūnas: Nanomaterial demand is growing every year. Nanomaterials are being used in cosmetics, medicine, food industry, and many other applications. It is estimated that the nanomaterial industry revenue reached $40 billion. One of the most promising areas is the application of nanomaterials for food production in packaging. The aim is to protect food from microorganisms. This can be achieved with the help of nanosensors.

Food quality can be affected by microorganisms, toxins, or pathogens, which can be detected with the help of fluorescence nanoparticles. Pesticides, antibiotics, and various types of allergens are detected with graphene oxide, and optical and electrochemical sensors that contain silver, gold, and iron nanoparticles. Nanotechnologies have changed the way food is stored, produced, tested, and packaged. It is now easier to maintain food quality and it is possible to avoid biological and chemical contaminations. Researchers from Lithuania and the United Kingdom work in this area. Nature Research Centre, Vilnius University Life Science Centre joined forces in the EU-funded project NEGOI to evaluate the new technology. The key purpose was to determine the efficacy of composite nanosilver and graphene oxide inks against bacteria and fungi.

Elena Servienė: The new material is an effective way to work against bacteria and fungi, i.e. to provide protection against them. We aim to demonstrate, that new materials are effective and can kill a wider range of microorganisms.

Rolandas Maskoliūnas: Most frequently used are silver nanoparticles, which are not only effective against werewolves, but also against invisible microorganisms not seen by the naked eye. Small dimensions of nanosilver allow for combating bacteria and fungi.

Elena Servienė: Silver nanoparticles have been researched globally by many research groups. The key principle of the antibacterial action of nanoparticles involves the interaction with the cell membrane, their disruption, and the killing of bacteria.

Rolandas Maskoliūnas: In recent years the variety of nanomaterials grew. One can attach many different materials to them including small peptides.

Elena Servienė: Nanoparticle can be functionalized with biocidal substances. Not necessarily chemical substances. It could be peptides. Their effect is rather different. The interaction is guided through receptors or through signal pathways, affects cell homeostasis, and leads to death.

Rolandas Maskoliūnas: Researchers of this project used cultivated bacteria, that were tested with nanosilver inks. Both gram-positive and gram-negative bacteria have been used. The two varieties are differentiated by the cell wall thicknesses and their components.

Elena Servienė: In this project, we used model Escherichia coli and Staphylococcus aureus bacteria. These bacteria represent Gram-positive and Gram-negative species. It was demonstrated that new inks are more effective against E. coli bacteria.

Rolandas Maskoliūnas: Researchers investigated, what is the minimum concentration of ink required to achieve the maximum inhibition. This is important as these new materials may be harmful to human beings or the environment. In the laboratory, one works with model microorganisms.

Elena Servienė: One may conclude that if the ink is effective against model E. coli it is likely to have a similar effect on other types of E. coli bacteria. Regardless of whether they are pathogen or non-pathogen.

Rolandas Maskoliūnas: It was observed that nanosilver and graphene oxide inks kill not only bacteria. This was confirmed by Vilnius University Life Science Centre researchers, who have demonstrated successful efficacy against fungi. Scientists from the United Kingdom also demonstrated efficacy against viruses. Lithuanian scientists are not only know for their work in semiconductor physics, but they are also not new to nanotechnologies.

Elena Servienė: Genetics Laboratory, where you stand right now, has a long history working with nanomaterials, in particular with functionalized nanoparticles. We have completed an EU-funded project, in which we investigated the antibacterial efficiency of nanomaterials functionalized with bioactive peptides.

Rolandas Maskoliūnas: Such work is very promising because microorganisms and various fungi, can cause great damage. In the best-case scenario, food is wasted, in the worst case it may result in food poisoning. Thus, nanomaterial-coated antipathogen packaging is required.

Elena Servienė: Speaking about the food industry, we have undertaken projects, where nanoparticles were functionalized with peptides, e.g. nisin, which is effective against various microorganisms. Against bacteria and fungi. It can protect food using coated packaging.

Rolandas Maskoliūnas: Lithuanian scientists not only investigate antimicrobial effects but also develop new nanomaterial production techniques.

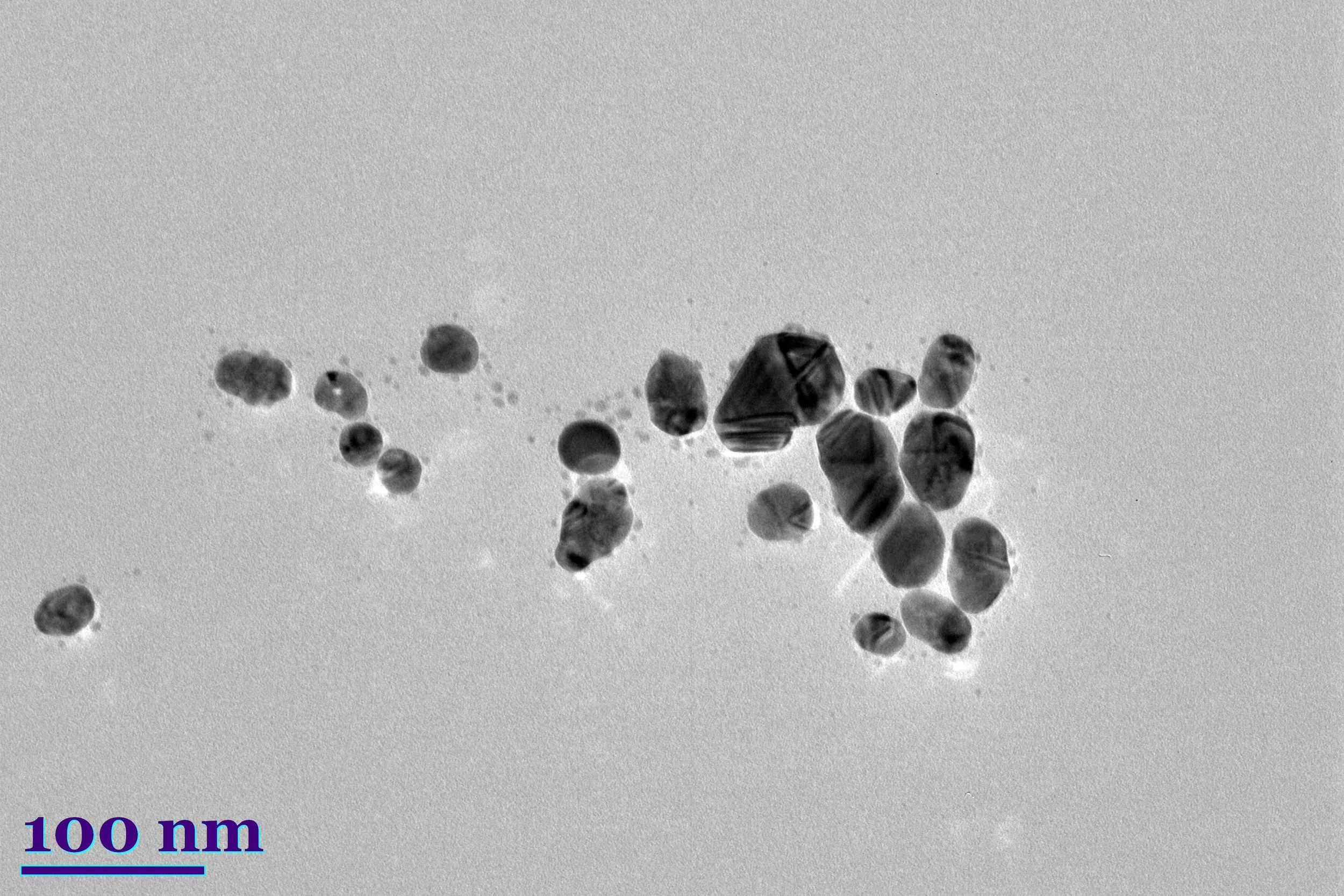

Gediminas Galinis: One of the main targets was to design a new generation reactor according to the patent production method. This technology is different from other methods. The key goal is to address the high waste problem, i.e. to reduce the number of non-nanomaterials in production, likewise, to increase energy efficiency.

Rolandas Maskoliūnas: The reactor is made of three main elements: material deposition, liquid flow, and a vacuum chamber in which the production of silver, copper, gold, and platinum takes place.

Gediminas Galinis: Currently, the most popular production process is chemical reduction. In this process, metal salts and reducing agents are dissolved in a solvent. Ions are reduced upon heating and nanomaterials form. Later, nanoparticles are separated from unreacted materials.

Rolandas Maskoliūnas: In this process metal salts are not used, instead, pure metal is used as a source. Metal is evaporated in a vacuum, and atoms land on the liquid surface and condense into nanoparticles.

Gediminas Galinis: Essentially the process begins with material deposition, which is undertaken with the help of thermal or plasma evaporation. Macroscopic metal is converted into atomic vapor – it is evaporated. Atomic vapors travel in a vacuum, land on the surface of the liquid, and on the surface of liquid atoms interact and form nanoparticles.

Rolandas Maskoliūnas: How to control their size? This depends on the vapor pressure and the number of collisions between atoms.

Gediminas Galinis: If one increases vapor pressure, then the particle size grows. A larger size results from a higher number of collisions between atoms. There is a high probability of forming larger particles. Furthermore, particle size can be controlled by the addition of surface-active materials. Surfactants do not allow particles to overgrow.

Rolandas Maskoliūnas: It is anticipated that in the next year, this technology will be used for the mass production of nanomaterials.

Gediminas Galinis: I am a co-inventor of this process, and I co-invented this process when studying at the University of Leicester. Jointly with the University of Leicester, a patent application was submitted, then I acquired full IP rights. Now I try to apply this patent in business for nanomaterial production and application in industry.

Rolandas Maskoliūnas: There is a wide range of nanomaterials perhaps even hundreds of them. In principle, any material can be converted into few-hundred-sized to few-thousand-sized atom nanoparticles. Interestingly, at this scale nanomaterials acquire unique properties. Casual material can find unique talents.

Gediminas Galinis: For instance, silver antipathogen properties become more pronounced because of the larger surface area. If we consider nanosilver applications for printed electronics, then nanosilver has a lower melting point than bulk silver. This allows to sinter and to form conductive paths at lower temperatures and enables the printing of conductive silver contacts on plastic. The possibility of printing on plastic has a high demand.

Rolandas Maskoliūnas: Comparing traditional small molecules and antibodies, that prevent virus reproduction and entering cells, nanotechnologies created materials that have other functions. They can bind viruses, imitate cell membranes and affect virus envelope (viral envelope binder). This extends antiviral therapy capacity.

Gediminas Galinis: There are many interesting applications. I have mentioned silver, i.e. antipathogen and printed electronics applications. Nanomaterials are also used in catalysis when converting one chemical substance into another. Gold nanoparticles even tend to be applied for cancer treatment. It can be realized as the carrier of drugs to the required location.

Rolandas Maskoliūnas: Nanomaterial helped in fighting the SARS-Cov-2 pandemics. Pfizer-BioNtech and Moderna vaccines used lipid nanoparticles, that transported RNR to human cells. Nanoparticles are being used as a transport vehicle for small drug molecules.

Gediminas Galinis: There are also carbo-based substances, i.e. fullerenes, nanotubes, and graphene oxide nanoplates, which were studied in this project. There are also platinum, semiconductor, and quantum dots – broadly speaking a very wide range of different types of nanomaterials, that can be used in medicine.

Rolandas Maskoliūnas: Mentioned nanoinks can be used to create effective air filtering systems that stop coronaviruses or other pathogens. Currently, there are tests being undertaken with graphene oxide and nanosilver inks. They are used to coat materials for air filters.

Gediminas Galinis: Here you can see uncoated cotton and synthetic PET and viscose fabric. And here you can see what coated textiles look like: cotton and synthetic fabric. This exact material is being used to make air filters. When air passes the filter material, 77% less micro and nanopathogens were observed. Here you can see the ink formulation which was created jointly with our partners. This is a dispersion of graphene oxide and nanosilver. The simplest way is to dip coat or spray.

Research work has been done to show that such coated filters are effective against viruses and bacteria, against fungi. It has been shown that a single pass of air reduces microorganism count by up to about 77%. The filter’s key function is to trap and avoid spreading by inhibiting growth.

Rolandas Maskoliūnas: It is important to mention that the coated air filter remains active for a prolonged period and can be used multiple times.

Gediminas Galinis: First air filters have been installed in Thailand schools working jointly with the air filter manufacturers and companies that agreed to use these filters. They are being used. In order for it to be used widely, biocidal product regulation compliance is needed. This new active substance must be authorized.

Rolandas Maskoliūnas: In summary Nature Research Center and their partners joint work and acquired knowledge will be transformed into high-technology based products, that will create safer environment for humans.